Plastic Injection Molding Services

Our Injection Molding Capabilities

At TechNH, we boast a wide range of injection molding capabilities to accommodate the unique requirements of each project. Our machinery allows us to mold a vast array of geometries with precision and efficiency. Whether it’s medical-grade moldings for healthcare devices, long-lasting components for water treatment, or high-precision parts for military applications, we have the expertise to deliver exceptional results.

We specialize in processing plastic components of various sizes and complexities to meet the diverse needs of our customers. From small, intricate components to large-scale geometries, we have the capabilities to mold parts ranging from 0.5 oz to 128 oz in shot weight and press range from 16 tons to 780 tons.

We work with a wide range of thermoplastic and engineering-grade resins. This versatility ensures that we can meet the specific needs of our clients across various industries, from medical devices to aviation.

Expert Consultation and Comprehensive Support

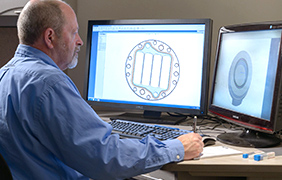

Our commitment to excellence extends beyond production. From the initial stages of design to the final delivery of parts, we provide comprehensive support and consultation to ensure the success of every project. Our team offers manufacturability feedback and consultative design services to help clients avoid mold design pitfalls and optimize production processes. With scientific molding techniques, we ensure high-quality parts consistently and reliably with every production run.

Quality Assurance and Precision

Quality is at the center of everything we do. Throughout the molding process, we employ rigorous quality assurance measures to maintain the highest standards of excellence. Critical-to-quality dimensions are closely monitored, and parts are qualified to ensure dimensional accuracy and consistency. Our molders optimize and monitor every aspect of the process, from fill speed to hold pressure, to deliver superior results with each production run.

Frequently Asked Questions

Plastic injection molding is a manufacturing process that involves filling a metal mold cavity with liquid plastic resin, which then cools and solidifies to form a plastic part. It is widely used for producing plastic parts at scale due to its efficiency, low material waste and cost-effectiveness.

A wide range of thermoplastic and engineering-grade resins can be used in the injection molding process, depending on the specific requirements. Each type of plastic has its own set of properties, making it suitable for different applications. For instance, ABS (Acrylonitrile Butadiene Styrene) is known for its toughness and impact resistance, while polycarbonate is chosen for its high strength and transparency. This versatility ensures that manufacturers like TechNH can meet the specific needs of our clients across various industries, from medical devices to aviation.

The cost of making a plastic injection mold can vary widely, depending on several factors, such as the overall complexity of the design, type of material (resin) required, the mold itself (i.e. the number of cavities in the mold) as well as the size of the mold. The costs can range from $1,000 to over $100,000.

Step 1: Clamping – The two halves of the injection mold are closed and clamped together using a hydraulic or mechanical clamping unit. This step ensures that the mold remains securely closed during the injection and cooling phases.

Step 2: Injection / Pack and Hold – In the Injection step, melted polymer is injected into the mold cavity, filing it 95-99% full. This step establishes the foundation of consistency between shots. Then, at the pack and hold step, as the material cools and begins to shrink, more material is added to the mold to ensure a complete fill.

Step 3: Cooling – Once the molten plastic fills the mold cavity completely, it begins to cool and solidify. This continuation of the cooling and shrinkage prepares the mold for opening and ejection.

Step 4: Mold Open – The part cools and releases from the sides of the mold at the parting lines.

Step 5: Ejection – After the plastic part has cooled and solidified, the mold opens, and the cooled part is pushed away from the mold cavity via ejection pins.

Scientific injection molding is an advanced method of injection molding that utilizes scientific principles and data to optimize the molding process. It aims to produce high-quality parts consistently by carefully controlling and understanding each phase of the process. Key principles and steps are as follows:

- Material Characterization – Understanding the properties of the material being used (such as viscosity, flow rates, and thermal properties) is crucial. This data helps in setting up the machine parameters correctly.

- Process Analysis – Scientific injection molding involves analyzing the entire molding process. This includes studying the flow of the material into the mold, the pressure and temperature profiles, and the cooling rates.

- Data-Driven Decisions – The process relies heavily on data collection and analysis. Parameters such as fill time, injection pressure, holding pressure, and cooling time are monitored and adjusted based on real-time data.

- DOE (Design of Experiments) – This is a systematic method to determine the relationship between factors affecting a process and the output of that process. In scientific injection molding, DOE is used to identify the optimal conditions for producing parts.

- Validation and Control – Once the optimal parameters are identified, they are validated through repeated trials. Control charts and statistical tools are often used to ensure that the process remains within the specified limits.