Tool Transfer Services at TechNH

Why Transfer Your Tool to TechNH?

If your current supplier delivers inconsistent or subpar parts, the integrity of your products and brand are at stake. TechNH’s robust quality control processes ensure your tools perform at their best.

Late deliveries disrupt supply chains and cost businesses time and money. Operating at a controlled 70% capacity, TechNH ensures we have the bandwidth to accommodate your project without delays.

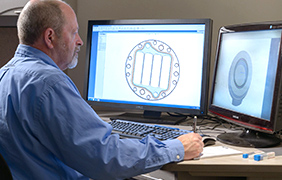

TechNH’s in-house engineering and tooling departments provide expert evaluations, recommending maintenance or modifications to optimize your tool for production. Our experience with transfer molds ensures seamless integration of your program into our systems.

When production needs outgrow your current supplier’s capabilities, TechNH’s wide range of press sizes and capacity planning guarantee we can handle both small and large-scale production needs.

TechNH’s Tool Transfer Process:

A specialized team, including an Engineering Program Manager and Regulatory Affairs Specialist, is assigned to oversee your tool transfer. This ensures every aspect of the process is expertly managed.

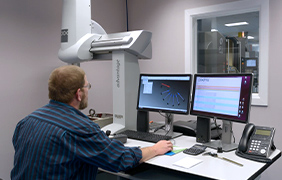

Our engineers assess the condition of your molds upon arrival, identifying any necessary repairs or enhancements. Our in-house tooling department is equipped to handle everything from minor adjustments to significant upgrades.

Using tools like Gantt charts, we map out every step of the transfer, from initial assessment to full-scale production, ensuring transparency and clear timelines.

Before production begins, we conduct sample runs to verify that all parts meet quality and regulatory requirements. This includes thorough documentation to ensure consistency and compliance.

Throughout the process, we engage with your team to leverage your insights and feedback, ensuring that the final output aligns with your specifications.