Quality

Beyond Compliance

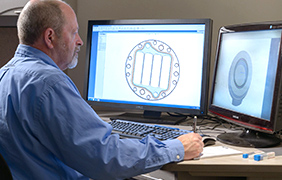

Our dedication to quality extends beyond compliance. We boast a state-of-the-art metrology lab staffed with trained quality engineers who meticulously scrutinize every aspect of production to guarantee adherence to the highest standards. Moreover, our regulatory department operates independently, ensuring that all processes undergo rigorous scrutiny and validation, free from the pressures of everyday production demands.

We understand that true quality is validated through traceability, repeatability, and meticulous documentation. That’s why we adhere to stringent validation processes, including PPAP and the IQ/OQ/PQ validation framework, particularly crucial in medical injection molding.

PPAP is a standardized process in the automotive and other industries to ensure that manufactured parts meet customer requirements. At TechNH, we employ PPAP to systematically validate and approve the production processes for new parts. By meticulously documenting every step of the manufacturing process and conducting thorough inspections, we ensure that our parts consistently meet or exceed customer specifications.

In medical injection molding, the IQ/OQ/PQ validation process is crucial for ensuring the reliability and consistency of manufactured parts. TechNH follows this rigorous validation framework, starting with Installation Qualification (IQ) to verify the proper integration of molds with our presses. Operational Qualification (OQ) ensures that molds produce parts consistently, while Process Qualification (PQ) scrutinizes every detail of the production process to ensure compliance with specifications. By adhering to this validation process, we guarantee the highest levels of quality and reliability in every part we produce.

TechNH employs APQP methodologies to proactively plan and manage quality throughout the product development process, ensuring that customer expectations are met and exceeded.

TechNH conducts Gage R&R studies to assess the reliability and consistency of measurement systems, ensuring accurate and precise quality control.

For customers requiring the pinnacle of quality and validation, TechNH stands ready to exceed your expectations. With our expertise and commitment to excellence, we’re equipped to help you achieve your most stringent quality standards and deliver unparalleled results.