In the world of injection molding, validation is more than just a box to check—it is a critical process that ensures your parts meet specifications, function consistently, and stand up to regulatory scrutiny. Whether you are launching a life-saving medical device, an industrial component, or a high-performance filtration system, the path to production must be reliable and repeatable.

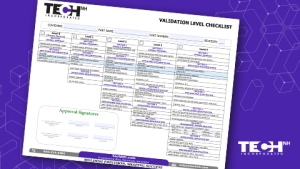

At TechNH, we developed a flexible Validation Checklist to bring structure, clarity, and confidence to this process. By offering scalable levels of validation, we help customers tailor their approach to balancing risk, cost, and compliance without overburdening a program.

What is the TechNH Validation Checklist?

The TechNH Validation Checklist is a tiered framework used to define the depth and scope of part and process validation. From simple low-risk components to complex, regulated assemblies, we align our process with your quality requirements from the start.

Our checklist outlines five validation levels (0 through 4)—each with a defined set of deliverables and documentation. This system helps avoid misunderstandings, accelerates timelines, and ensures everyone is aligned on expectations.

Breaking Down the Validation Levels

Each validation level builds upon the last, adding more precision, traceability, and documentation as needed:

Level 0: Minimum Required

- Signed sample approval form

- Drawings and internal inspection docs (ORS & IPI)

- Basic alignment on fit and function

- Best suited for: Low-risk commercial parts

Level 1: Standard Process

- Adds signed validation protocol and report

- Includes material certifications and calibration certs

- Introduction of frozen validated processes

- Ideal for: Moderate-risk applications requiring traceability

Level 2: Enhanced Documentation

- Operational qualification (OQ) elements introduced

- Bubble drawings and 3-piece First Article Inspection (FAI) per cavity

- Capability studies for nominal conditions

- Used for: Parts requiring deeper process control and quality oversight

Level 3: Full Installation & Operational Qualification

- Mold installation and set-up checklists

- Process Flow Diagram, PFMEA, and Control Plan included

- Capability studies for high, low, and nominal settings

- Suited for: Regulated industries like medical or aerospace

Level 4: Complete Validation with PQ & MSA

- Performance Qualification (PQ) with three production runs

- Gage R&R and full Measurement System Analysis (MSA)

- Type 1 & Type 2 studies for all critical to quality (CTQ) dimensions

- Essential for: Medical device submissions and high-stakes production

Tailored to Your Risk Profile

Not every program requires a full validation suite. Our experienced team works with you to select the level that makes the most sense—based on part complexity, regulatory requirements, and your internal quality system. Whether you are pursuing ISO, FDA, ITAR, or you simply need repeatable excellence, we scale our support to match your goals.

Why a Structured Validation Approach Matters

- Reduces risk of failed launches or nonconforming parts

- Establishes a documented process for audits and quality reviews

- Enables consistent production, even across different shifts or facilities

- Saves time and money by addressing issues early

- Improves collaboration between customer and supplier

Download the Validation Checklist

If you are preparing to launch a new molded part—or requalify an existing one—we invite you to explore our Validation Checklist and see how TechNH can support your success. Let’s take the guesswork out of quality and build a validation strategy that fits your needs.

Have questions? Reach out today and let’s talk through your next program.