Our Expertise

TechNH’s expertise in defense-grade plastic injection molding encompasses a wide range of applications, including:

- ITAR Compliance: TechNH has been an ITAR-registered partner since 2010, demonstrating our commitment to compliance with regulations governing the export and manufacture of defense-related products. We adhere to strict security protocols to safeguard sensitive information and ensure regulatory compliance at every stage of the production process according to Directorate of Defense Trade Controls (DDTC) regulations.

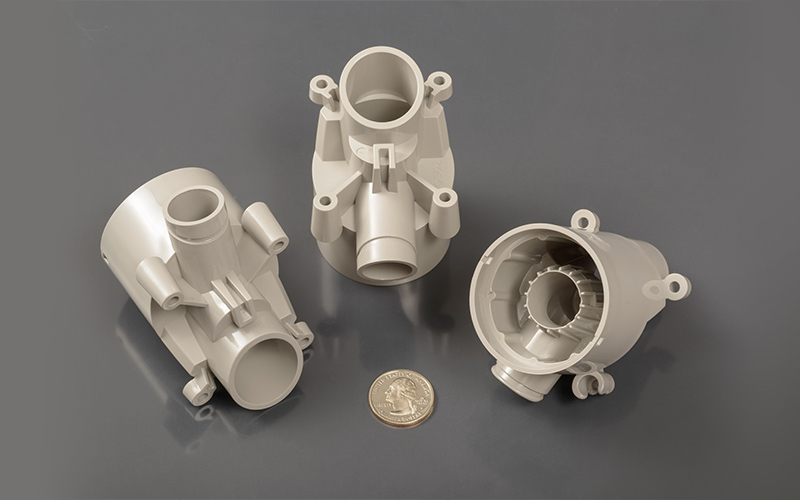

- Specialized Components: We manufacture precision-engineered components that meet the rigorous standards of defense equipment, ensuring reliability and performance in challenging environments.

- Custom Assemblies: Our capabilities extend to producing custom assemblies for defense applications, integrating multiple components into cohesive units that meet specific operational requirements.

- Toughness and Durability: We understand the importance of durability in defense applications. That’s why we utilize advanced materials and manufacturing techniques to produce parts that can withstand the harshest conditions and stresses.

Why Partners Choose Us

When you partner with TechNH for your defense-grade plastic injection molding needs, you can expect:

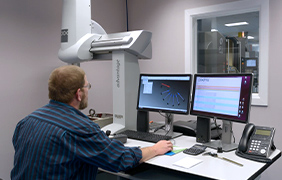

We uphold the highest standards of quality and precision in everything we do. Our stringent quality control processes ensure that every component meets or exceeds the most demanding specifications.

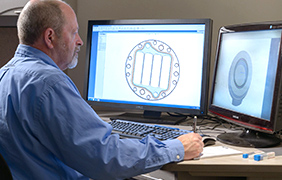

With a team of seasoned professionals and decades of experience in the defense industry, we have the knowledge and expertise to tackle even the most challenging projects.

At TechNH, we understand the critical nature of defense applications. That’s why we prioritize reliability and consistency in our manufacturing processes, delivering products that perform flawlessly in mission-critical scenarios.

We believe in forging strong, collaborative partnerships with our clients. From initial concept to final delivery, we work closely with you to understand your needs and objectives, ensuring that we deliver solutions that exceed your expectations.

As technology evolves, so do we. We’re constantly investing in new technologies and techniques to stay ahead of the curve and deliver cutting-edge solutions to our defense partners.

Get In Touch

Ready to partner with a trusted leader in defense-grade plastic injection molding? Contact TechNH today to discuss your project and discover how we can help you achieve your objectives with precision, reliability, and excellence.

Frequently Asked Questions

Injection molding is well suited for defense-grade and military applications because the process delivers exceptional repeatability and consistency—an important factor for mission-critical components. Further, the injection molding process offers material versatility with high-performance engineering polymers that withstand extreme temperatures, resist chemicals, and endure harsh environments from arctic cold to desert heat. Injection molding can create parts with complex geometries in a single-piece construction, eliminating assembly steps and potential failure points while reducing weight.

Design flexibility enables integration of multiple functions into single components, while cost efficiency works for both large production runs and mid-volume specialized parts. The process supports material traceability and lot control essential for defense applications, achieving dimensional precision necessary for critical interfaces. Tech NH combines advanced injection molding capabilities with deep understanding of defense requirements to deliver components meeting stringent military specifications.

Defense injection molding requires ITAR (International Traffic in Arms Regulations) compliance for handling defense-related data and components with strict access controls and personnel vetting. AS9100 quality management systems extend ISO 9001 with aerospace-specific controls, while MIL-STD specifications define exact requirements for materials, processes, and documentation.

Material certifications must include complete traceability with supplier certificates of compliance showing the material meets military specifications. Dimensional tolerances frequently require precision of ±0.001 inches or tighter, verified through documented inspection using calibrated measurement equipment. Testing includes first article inspection (initial sample validation per AS9102 standard), material property verification, and environmental stress testing. Documentation demands detailed process control plans, statistical process control (SPC) data tracking quality over time, and complete inspection records. Tech NH maintains the rigorous quality systems, security protocols, and documentation practices required for defense work.

Defense parts prioritize performance-assurance over cost-optimization, incorporating redundant features, higher safety factors, and fail-safe mechanisms. Designs must function in conditions that could be more harsh than those common to commercial parts. Injection-molded parts for defense must meet specifications to withstand extreme temperature ranges (-65°F to +160°F or beyond), resist UV degradation, withstand shock and vibration per MIL-STD-810, and maintain properties despite chemical exposure.

Material selection emphasizes performance with engineering-grade resins like PEEK or glass-filled nylons. Specifications reference military standards with mandatory traceability to certified lots. Validation processes include material testing (DSC, tensile strength, impact resistance), environmental simulation, and functional validation in assemblies. Statistical validation demonstrates process capability with ongoing SPC monitoring. Tech NH’s engineering team brings extensive defense experience to ensure parts meet operational requirements while maintaining manufacturability.

Typical challenges companies encounter when selecting a supplier for defense injection-molding services includes finding a supplier with updated certifications. Suppliers must maintain ITAR registration, implement DFARS cybersecurity controls, conduct personnel background checks, and maintain physical security. These are requirements that many capable molders cannot meet. Defense work demands AS9100 certification, documented special processes, calibrated inspection equipment, and statistical process control infrastructure.

Evaluating technical capability proves difficult—suppliers may claim defense experience but lack engineering depth for complex geometries, tight tolerances, or difficult materials. Capacity concerns might arise because defense programs involve lower volumes yet require long-term commitments. Supply chain transparency is mandatory but challenging, requiring visibility into all materials and sub-tier suppliers. Communication and responsiveness prove essential as defense programs require rapid response to engineering changes and government inquiries. Tech NH has built its business around defense requirements, combining security compliance, quality systems, and technical expertise for mission-critical components.