Tool Transfer Services at TechNH

Why Transfer Your Tool to TechNH?

If your current supplier delivers inconsistent or subpar parts, the integrity of your products and brand are at stake. TechNH’s robust quality control processes ensure your tools perform at their best.

Late deliveries disrupt supply chains and cost businesses time and money. Operating at a controlled 70% capacity, TechNH ensures we have the bandwidth to accommodate your project without delays.

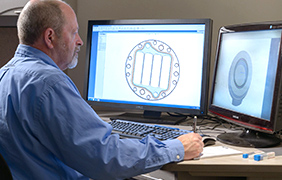

TechNH’s in-house engineering and tooling departments provide expert evaluations, recommending maintenance or modifications to optimize your tool for production. Our experience with transfer molds ensures seamless integration of your program into our systems.

When production needs outgrow your current supplier’s capabilities, TechNH’s wide range of press sizes and capacity planning guarantee we can handle both small and large-scale production needs.

TechNH’s Tool Transfer Process:

A specialized team, including an Engineering Program Manager and Regulatory Affairs Specialist, is assigned to oversee your tool transfer. This ensures every aspect of the process is expertly managed.

Our engineers assess the condition of your molds upon arrival, identifying any necessary repairs or enhancements. Our in-house tooling department is equipped to handle everything from minor adjustments to significant upgrades.

Using tools like Gantt charts, we map out every step of the transfer, from initial assessment to full-scale production, ensuring transparency and clear timelines.

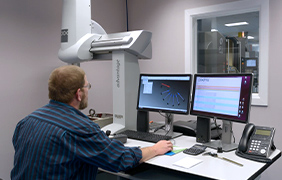

Before production begins, we conduct sample runs to verify that all parts meet quality and regulatory requirements. This includes thorough documentation to ensure consistency and compliance.

Throughout the process, we engage with your team to leverage your insights and feedback, ensuring that the final output aligns with your specifications.

Frequently Asked Questions

A tooling transfer in injection molding is the process of relocating existing molds and dies from one manufacturing facility to another. A company needs to physically move the tooling and transfer all technical documentation, including process parameters and quality specifications to ensure seamless production at the new location.

Companies pursue tool transfers for several key reasons: cost reduction when finding suppliers with better pricing, quality improvements when current vendors fail to meet specifications, capacity needs when existing suppliers can’t meet demand, geographic advantages to reduce shipping costs, or consolidation of suppliers. The transfer process requires meticulous planning and thorough validation to avoid production disruptions. Tech NH specializes in seamless tool transfers to minimize disruption and keep production humming, with comprehensive evaluation and validation services to ensure molds perform optimally from day one.

Minimizing risk and maintaining quality when transferring injection-mold tools between vendors requires a methodical, documentation-driven approach. As best practice, start with a comprehensive tool audit documenting current condition through photographs, measurements, and wear assessment. Secure all original drawings, material certifications, process parameters, and quality control data. Create a detailed transfer plan covering proper crating, insurance, and climate-controlled transportation.

Once the injection mold tooling has transferred, upon arrival, the receiving injection molding company should conduct an immediate inspection before setup.

Upon arrival, conduct immediate receiving inspection before setup. Run test shots in stages—starting with partial fills to verify flow patterns, then progressing to complete parts. Compare these initial parts against approved reference samples from the original supplier using formal first article inspection. Plan for iterative optimization as process parameters may need adjustment for different equipment or environmental conditions. Tech NH’s experienced team follows rigorous protocols to minimize risk and downtime for every transfer.

A comprehensive checklist for successful injection molding tool transfer should cover:

- Pre-Transfer – document mold history, capture process parameters, photograph the tool, obtain material certifications and golden samples, verify IP rights.

- Logistics – select appropriate crating with desiccants, arrange climate-controlled shipping, ensure insurance coverage, coordinate timing.

- Receiving – inspect for shipping damage immediately, clean and preserve the tool, inventory all components.

- Validation – install and perform dry cycles, progress through short shots and optimization, complete first article inspection, run production quantities to verify consistency and yield.

Tech NH’s structured process addresses each critical step systematically for smooth transitions.

Common pitfalls or challenges in injection-molding tool transfers can include:

- incomplete documentation forcing costly trial-and-error

- hidden tool damage revealed only during setup

- equipment incompatibility requiring adapters or modifications

- material supply differences causing unexpected variation

- loss of undocumented operator techniques

An accelerated transfer is one thing, but a rushed timeline can compound these risks when companies skip critical validation steps.

Keep lines of communication open, as communication breakdowns between vendors can leave critical questions unanswered. Further, measurement system differences can falsely indicate parts are out of specification. Finally, keep an eye on environmental factors, because humidity or temperature variations between facilities may affect material behavior and process stability.

Tech NH mitigates these pitfalls through thorough pre-transfer assessments, detailed documentation protocols, and extensive validation testing.